This past Christmas I received a book about the history and unique characteristics of the Bowie knife. It explained in detail, what goes into making a high quality knife. My attention was captured for some time as I devoured the book’s pages, one by one. I had heard of the author, Bill Bagwell, before, and knew that he was a well known bladesmith. He claims that “the Bowie is the most effective fighting and survival knife ever made.” I wanted to learn more. I had no knowledge as to why it is supposedly such an effective outdoor knife. I was intrigued by Bagwell’s claim. What was the Bowie’s role in history and why is it such an effective outdoor knife compared to other knives?

As an Eagle Scout, having spent a number of years hiking and camping, I have developed an appreciation for the design and utility of well-made knives. My assumption before this was that the Ka-Bar was the most effective overall outdoor knife ever made because the Ka-Bar is famous for being the knife of the Marine Corp. It also happens to have the longest steel manufacturing process description of all the knives in any catalog in my library (bathroom).

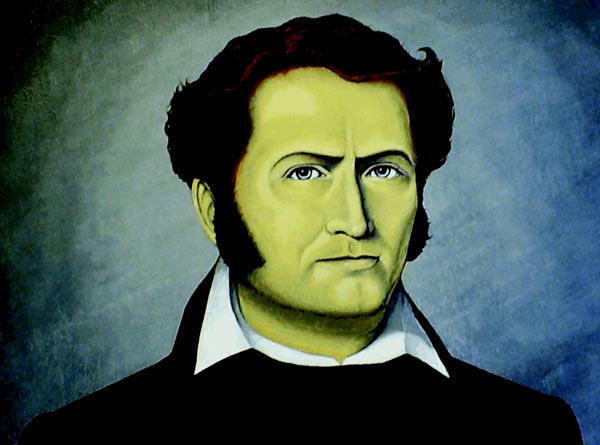

It turns out that the original Bowie knife was not actually made by Jim Bowie himself, but by his brother, Rezin Bowie, as he explained, “The first Bowie knife was made by myself in the parish of Avoyelles, in this state [Louisiana], as a hunting knife, for which purpose, exclusively, it was used for many years…” It is said that in 1826, in Alexandria, Louisiana, James had an unpleasant encounter with Sheriff Norris Wright, in which he was shot at by the Sheriff, so Rezin gave James the knife. “I presumed that a second attempt would be made by the same person to take his life, so I gave him the knife to be used as occasion might require, as a defensive weapon,” said Rezin Bowie. The exact design of the knife is unknown, but most historians believe that it looked like what is called the primitive Bowie today. Sure enough, James got into another fight not long after, in which Rezin’s knife saved his life.

Over the next few years, an Arkansas blacksmith named James Black made a good number of knives for James Bowie which had thick, ten to fifteen inch blades, brass hand guards, and a curved clip

point tip. James Bowie carried these knives from the late 1820’s to the early 1830’s through several victorious knife fights. It was during this period and by these knife fights, that made James Bowie with his big knife on his side so notorious, and the term “Bowie Knife” came to be. By the beginning of the 1830’s, Bowie knives were being made across the country and even in the city of Sheffield, England, which is still the major cutlery manufacturing city of the United Kingdom.

The Texas revolution began on October 2, 1835 and James Bowie accepted the offer of serving as a colonel in the militia. A year later, Colonel Bowie died in the battle of the Alamo. Soon after James

Bowie’s death, the popularity of the Bowie knife increased dramatically. Everyone wanted a knife with the name “Bowie” stamped onto it to remember him by, and even smaller knives carried his name

because it made them sell.

Although the battle of the Alamo occurred in the state of Texas, and the Bowie is usually thought of as a Texan knife, it was in and around the city of New Orleans and along the Mississippi river from

the 1830’s through the 1860’s that the Bowie knife’s physical characteristics evolved. The original Bowies were built specifically for the job of knife fighting and with a closer look at the environment in and around New Orleans during this period, it is easy to see why the knife design was perfected there.

By 1830, New Orleans housed the second largest port of the United States. This, along with the connecting Mississippi River, made the city a wealthy and important trade center. Up until the Louisiana Purchase in 1803, the region was controlled by the French and the city remained culturally European long after the purchase. The city attracted wealthy people from all over Europe, particularly fencing masters who craved the so-called wild life of living in America. Piracy in the Gulf of Mexico was also rampant at this time, and the majority of pirates were skilled swordsmen with their 25-30 inch cutlasses.

In these years, the knife was considered the most effective concealable weapon in close quarters fighting because small firearms were so inaccurate and sluggish to load and fire. Because of this, wealthy people were willing to pay large sums of money to blacksmiths to develop the perfect knife, giving birth to the deadliest knife ever known—the Bowie.

There is a difference between the ideal fighting Bowie and an ideal survival Bowie, even though the basic design is relatively similar. The ideal fighting Bowie and survival Bowie would have roughly the same blade length of about nine to ten inches, because this is the length that offers the perfect amount of balance and leverage in both scenarios. But the ideal survival Bowie might be a fair amount

heavier overall and have a greater concentration of the weight further up the blade. This concentration of weight further up the blade gives the Bowie a balance more like a hatchet, so that it has greater chopping power, separating it from the more nimble fighting Bowie class.

“Most edged weapons have a specialty. For example, some slice or slash; razors come to mind here. Others, such as the kukri or cleaver, are primarily power weapons and chop at best. Icepicks, spikes, and daggers have penetration as their specialty. The Bowie stands alone among the edged weapons of the world in that it is the only knife that will make all of the cuts as well as the specialty weapons themselves and in some cases even better. A good Bowie will slice like a razor, chop like a cleaver and very nearly as well as a kukri, and will, in fact, stab and penetrate better than a dagger,” explains Bagwell. This quote pretty well sums up why the Bowie is the most effective fighting and survival knife ever made.

So why are so many hollow handled saw back knives sold these days? This is because of marketing. When people saw the Rambo movies, everyone wanted a knife like his. Realistically however, a hollow handle used for holding matches or fishing line only robs the sturdiness and balance of a full tang construction and the saw on the back of a knife makes it much more dangerous to handle—and it won’t cut wood any faster than another knife can chop through it. But the fact is, commercial manufacturers have to keep up with these trends and build whatever will sell, not whatever will work best.

Another classic example of how marketing affects cutlery is the type of steel used in commercial knives. Ninety-nine percent of commercially made knives today are made out of what is called “surgical”

stainless steel. People see the word “surgical” and assume that it is superior steel, but in reality, it is a more brittle, difficult to sharpen steel and won’t hold an edge. The only advantage to stainless is that it doesn’t tarnish very easily, making it well suited for kitchen knives, surgeons’ scalpels or artwork, but for an outdoor knife, it is an unwise choice.

The most common steel used to make pretty much any piece of cutlery from before 1900 was high carbon steel. This type of steel is much stronger than stainless, will hold an edge longer and is quicker

to sharpen. High carbon is an all around better steel for knives than stainless with the only downside that it tarnishes easily, and will rust if not given a finish or seriously neglected.

The third and final type of blade is called Damascus. This type of blade is made from anywhere between 250 and 1,100 layers of steel and iron that have been folded and forged together. Damascus blades have proved themselves as the most durable and legendary blades of all time. So much skill is required to properly forge the layers together that, today, only a handful of the most skilled bladesmiths can create this type of blade properly.

To make things even more complicated, the tempering process of the blade is almost as important as the type of steel used. Tempering means that the steel is heated and then cooled at a selected speed

which determines how hard the steel is. Just because a particular type of steel is hard, does not mean that it is strong. A glass window is an example of this. Glass is very hard but by no means is it strong. The faster steel cools, the harder and more brittle it is. The slower the steel cools, the softer and stronger it is.

New Orleans bladesmiths from the early 1800’s mastered the tempering process in which the back bone and handle of the blade are cooled very slowly to make it incredibly strong and flexible while the

edge is cooled very quickly to make it hard and hold an edge well. No commercial cutleries temper their knives in this way. A custom knife tempered this way will likely cost well over $1,000 and require

a six month wait.

So, where is one to find a well made Bowie that is still affordable? While there are some well balanced knives costing under $300, they don’t have the varied heat tempered blades that I just described. This problem is what prompted me to think of starting a bladesmithing business of my own. Would it be possible for me to learn to make high quality custom Bowie knives myself?

Time will tell. As you read these pages, I have started to craft my first, custom made knife. If it all works out, who knows? Maybe you’ll see an ad in a future issue of this magazine, offering custom

made “Alex” (Bowie) Knives for sale!